This template uses custom.

HOW IT ALL STARTED?

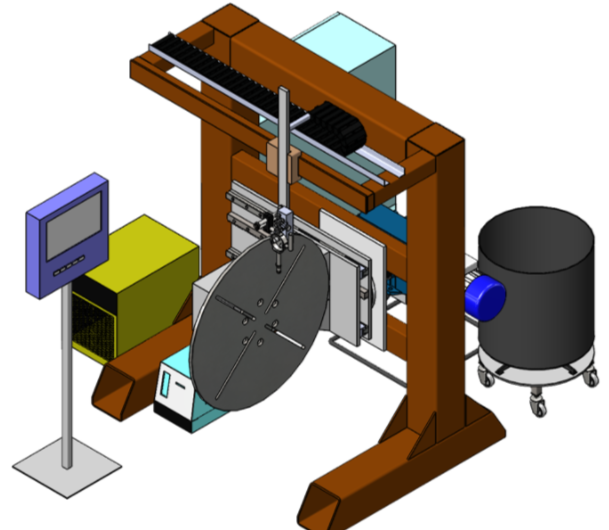

The IRON PROtection company was founded in 2020. An international welding engineer (IWE), dealing with the issue of protecting industrial equipment from abrasive wear, designed and manufactured a plant for applying carbide coatings to a sheet metal base.

The IRON PROtection company was founded in 2020. An international welding engineer (IWE), dealing with the issue of protecting industrial equipment from abrasive wear, designed and manufactured a plant for applying carbide coatings to a sheet metal base.

1

2

OUR

SERVICES

Technologies and materials for the application of carbide reinforcing coatings with high resistance to abrasive, shock, erosion and thermal loads, as well as the effects of friction and cavitation.

If you need to increase the working life of new original components and parts, or restore equipment that was already in operation, we are ready to help.

If you need to increase the working life of new original components and parts, or restore equipment that was already in operation, we are ready to help.

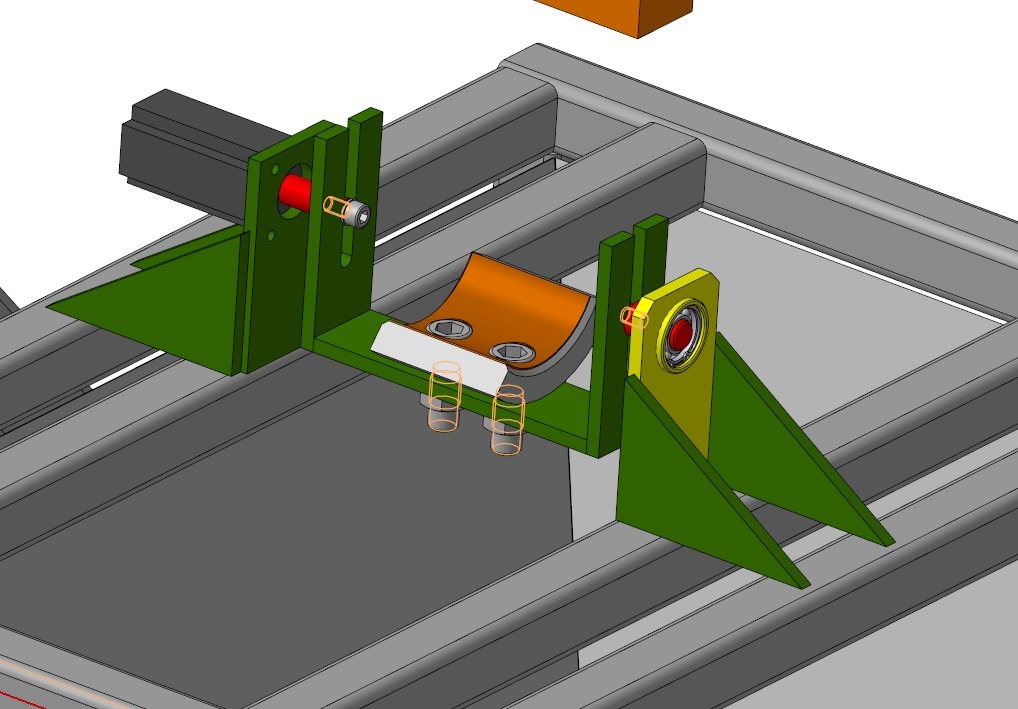

Development, production and application of installations for the application of carbide protective coatings.

3

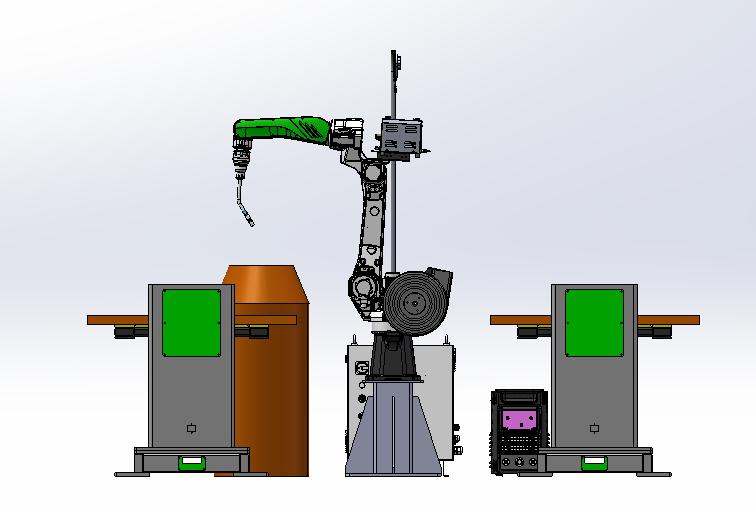

Programming of industrial robots FANUC, DAIHEN, KUKA.

Modern industry requires advanced solutions to optimize production flows.

Robotic welding is your key to reducing costs and improving product quality.

Modern industry requires advanced solutions to optimize production flows.

Robotic welding is your key to reducing costs and improving product quality.

Quality is doing something right, even when no one is watching.

Henry Ford

1945

14

99%

OUR ACHIEVEMENTS

>30

Assembled surfacing units

Successfully completed orders

Industrial robots have been into operation

4

2000m

Bimetallic wear-resistant plates have already been produced on our machines

43

Parts manufactured for cement production and mining industry

New production sites

2

Prev.

Next

2020- 2024

Year

GALLERY

HOW IT WORKS?

ROBOT PROGRAMMING AND TOOLING DESIGN

Our specialists come to your production site and adapt automated complexes to the tasks set.

1

TECHNICAL AUDIT AND SURFACING SERVICE

We carry out a set of measures to combat abrasive and related types of wear and offer solutions to increase the service life.

The purpose of applying the technology of applying carbide protective coatings is to increase efficiency, reduce downtime and the cost of replacing parts and assemblies.

The purpose of applying the technology of applying carbide protective coatings is to increase efficiency, reduce downtime and the cost of replacing parts and assemblies.

2

3

MACHINES FOR APPLYING WEAR-RESISTANT COATINGS

WE OFFER A UNIQUE CONCEPT OF COOPERATION.

THE BASIS OF OUR BUSINESS REMAINS THE PRODUCTION OF MACHINES FOR THE MANUFACTURE OF BIMETALLIC PLATES AND PIPES, AS WELL AS A SET OF EQUIPMENT FOR THE REPAIR OF VERTICAL MILLS

THE BASIS OF OUR BUSINESS REMAINS THE PRODUCTION OF MACHINES FOR THE MANUFACTURE OF BIMETALLIC PLATES AND PIPES, AS WELL AS A SET OF EQUIPMENT FOR THE REPAIR OF VERTICAL MILLS

Frequent questions

We can produce modular assembly directly on the customer's premises, anywhere in the world, thanks to unique technical solutions. Our equipment works successfully in Europe and the CIS

Our specialists, taking into account your technical specifications, can create an atypical project and bring it to life. You will be provided with a detailed description of all components and assemblies, as well as the opportunity to adapt it to your production tasks.

The whole process from the moment of signing the contract to commissioning takes 3 months. If the equipment is non-standard, the period may increase to 4 months.

OUR NEWS

Our team has been leading innovative developments of equipment and a new production method for wear-resistant bimetallic plates for several years.

Fundamentally different solutions allow us to deviate from classical coating methods. This technology is environmentally friendly and increases productivity by 7 times relative to surfacing with tapes or self-protective wires, consumes a minimum of electricity and allows you to get a perfect coating without defects. Version 2.0, under the working title "CUBE", will be presented at the International Welding Exhibition in Germany.

Fundamentally different solutions allow us to deviate from classical coating methods. This technology is environmentally friendly and increases productivity by 7 times relative to surfacing with tapes or self-protective wires, consumes a minimum of electricity and allows you to get a perfect coating without defects. Version 2.0, under the working title "CUBE", will be presented at the International Welding Exhibition in Germany.

APPLICATION

INCREASED REQUIREMENTS FOR LINING QUALITY HAVE LED TO THE INTRODUCTION OF NEW TECHNOLOGIES AND THE APPEARANCE OF BIMETALLIC FUSED PLATES IN MASS PRODUCTION. THE IDEA IS TO APPLY FINELY DISPERSED CHROMIUM CARBIDES WITH SPECIFIED CHARACTERISTICS TO LOW CARBON STEEL SHEETS IN AN AUTOMATIC MODE

CONSTRUCTION & MINING

Currently, losses from abrasive wear at large mining enterprises amount to millions of euros annually and include:

• Replacement of worn-out equipment components

• Lost profits from downtime

• Logistics costs, in remote areas

• Replacement of worn-out equipment components

• Lost profits from downtime

• Logistics costs, in remote areas

7%

Of all repair costs, the annual damage from abrasive wear in the mining industry is

COMPANY IRON PROTECTION, manufactures machinery and equipment for the manufacture of bimetallic plates, pipes, and surfacing repair of grinding equipment, as well as a supplier of technologies in this field

LINING OF MINING EQUIPMENT

PARTNERS

OUR PRODUCTS

To receive the full catalog, leave a request and we will contact you.